Development of a biomass char roller grinder and briquette composition analysis.

MIT D-Lab class

Introduction to Energy in Global Development

Community partners

- Community of Kpong

- Volta River Authority

- Kwame Nkrumah University of Science and Technology

Country

Ghana

Student team

MIT students unless otherwise noted.

- Kevin Lin Yang, TPP '25

- Jazmin Mucino, TPP '25

- Estelle Martin, TPP '25 and Aeroastro

- Aakriti Dhital, MBA '25

- Ridhi Aggarwal, Harvard

- Kartikeya Bhatotia, Harvard

Problem framing

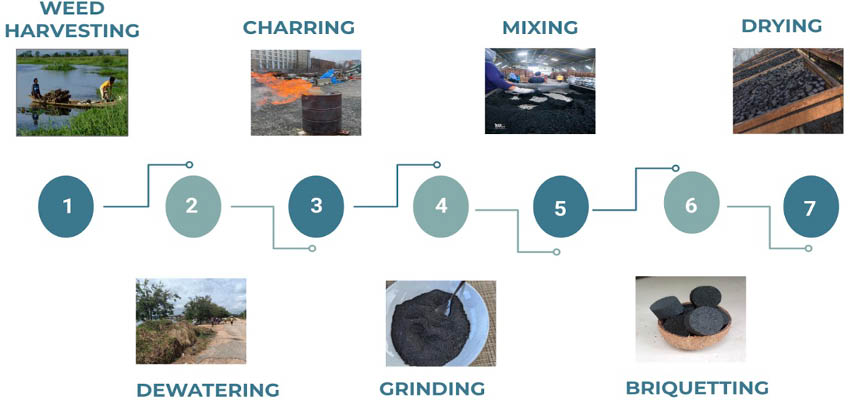

The Lower Lake Volta region in Ghana is grappling with a severe infestation of invasive aquatic weeds, particularly water hyacinths, which pose significant threats to hydroelectric power generation and local economic activities. Our project addresses this challenge by converting these weeds into charcoal briquettes for energy use.

The community faces primary challenges in this conversion process:

- Labor-intensive and time-consuming grinding

- Poor briquette quality

Cultural context

The local community in Kpong relies on fishing, navigation, and aquaculture, which are threatened by the weed infestation. Additionally, energy supply challenges make sustainable sources a priority.

Technical solution

Our grinder prototype comprises a base, roller, and feeder structures. The base offers stability and a catchment area, while the roller structure holds the roller’s metal shaft. The feeder directs biomass to the roller, reinforced with a steel sheet for durability. We've also developed various roller materials and patterns to optimize output particle size, throughput, and health risks.

For briquette recipes, we've shortlisted 50-50 mixes of aquatic weed with sawdust and corn cobs due to their promising durability and calorific values. Despite high moisture content, these briquettes show potential. Sawdust mixes heat water quickly but are less fuel-efficient, while corn cob mixes offer better long-term fuel efficiency.

Next steps

Moving forward, we aim to refine production processes and scale up operations to meet community needs. The iterative design process sets a foundation for enhancements, including motorization for increased output. Prioritizing safety and health, ongoing collaboration with local partners will refine cost estimates and ensure financial viability. Our goal is to demonstrate a successful model of local resource utilization for energy production.

Contact

Dan Sweeney, MIT D-Lab Lecturer and Research Scientist

Jazmin Mucino, Team member